Multi-Drive

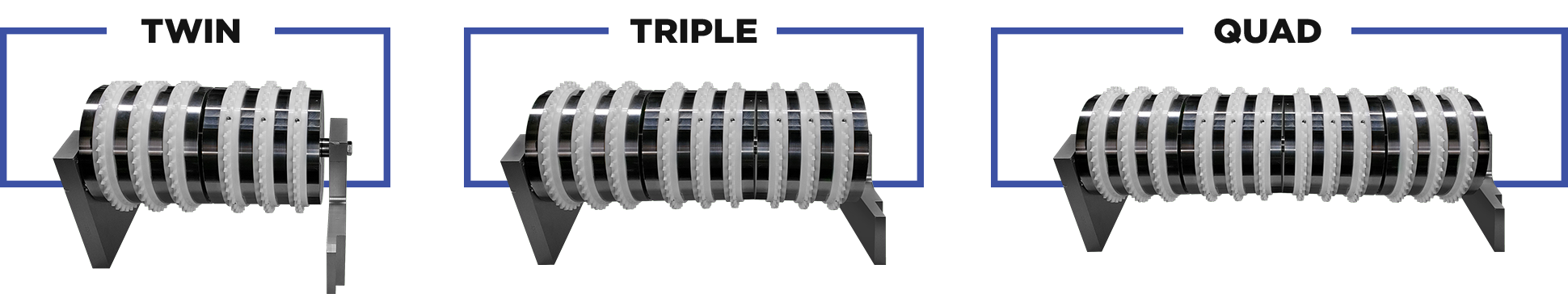

The Multi-Drive™ by Mag-Drive provides the ability to power up to 4 conveyor belts on the same shaft.

High Performance

Mounted on one end, the powered hub offers a variety of application uses. As with all One Motion™ mag-drive configurations, it can be coupled with encoders to create a smart belt system, perfect for infeed and other applications.

There is no time wasted to spool up a gearbox, no backlash, indexing with 1/16″, and acceleration that exceeds that of a conventional servo motor system.

Custom Design

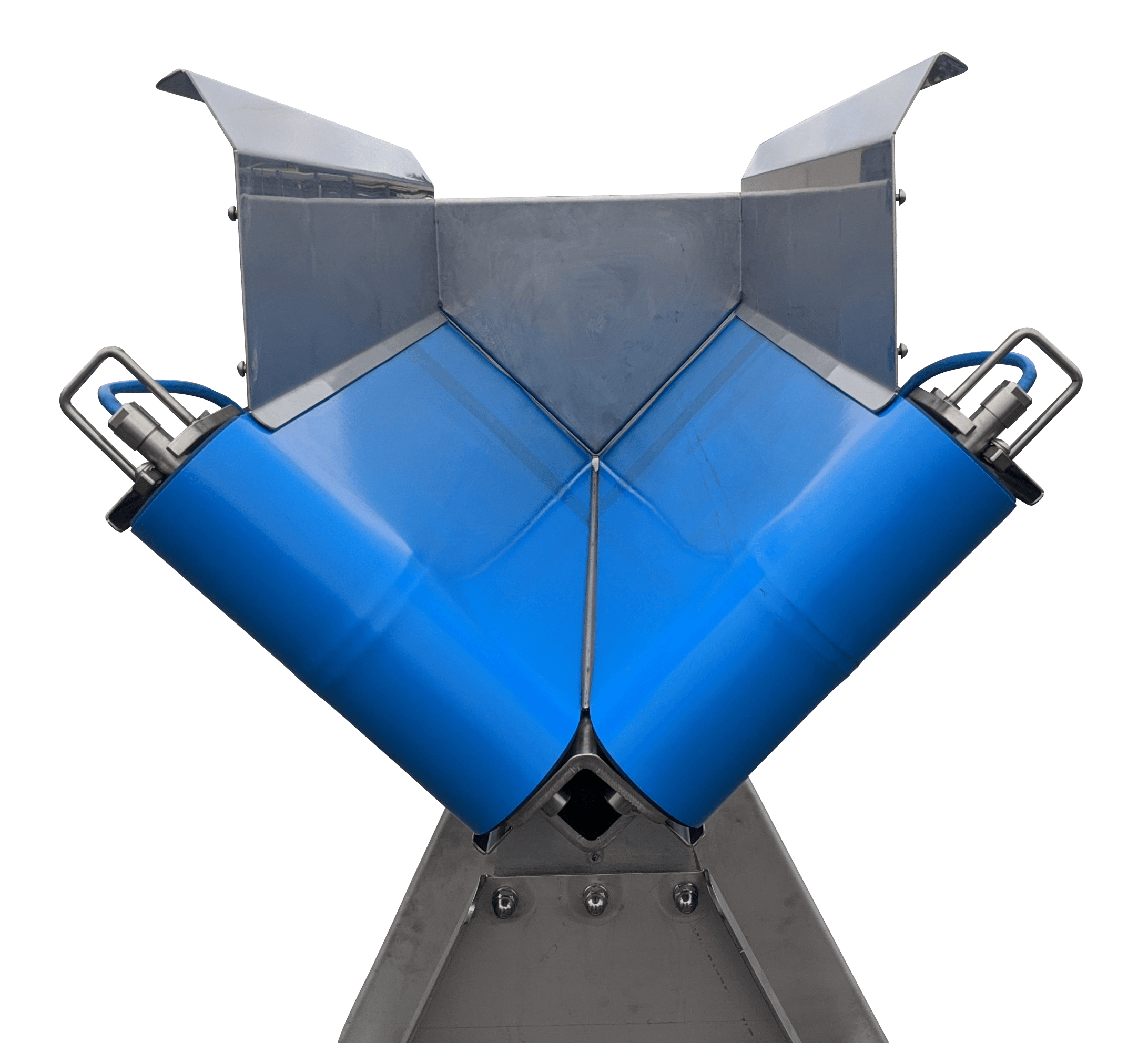

The Multi-Drive™ provides a plethora of possibilities. One example of this is the V-belt Machine which arranges two drives into a “V” shape (manufactured by Heinzen). Depending on your project needs, the Multi-Drive™ may be the perfect solution.

Rather than offering a one-size-fits-all product, our engineers take a “First – Time – Right” approach, taking the time to design, develop and build automation into packaging automation projects.

Product Alignment

Position Next to Feed or Discharge

Product Merge

As Small as 58mm Pulley Diameter

Hygienic Design

By embedding Mag-Drive drum motors inside the main components of the wrapper, crevices and cavities that are usually present when designing machinery with conventional motors, servo motors and gearboxes are eliminated. The sanitary construction of the flow wrapper makes it quick and easy to clean.

Advantages of the Multi-Drive

The Mag-Drive Multi-Drive drum motors or motorized pulleys, are maintenance free with no external moving parts — it is safe. The Multi-Drive magnetic pulleys are also simple to install and can replace existing drives without conveyor modification. Available in stainless or steel, Mag-Drive products are ideal for HACCP inspected locations where they eliminate contamination from hard-to-clean external motors, couplers, chain drives, and oil leaks. And in wet areas where electric power is hazardous, including fishing vessels, this drum motor easily withstands high pressure saltwater wash downs.

Safe

No rotating parts outside a roller

Belting

Used with belting such as PVC, modular steel, plastic

Space Saving

Saves up to 20” of valuable space

Controllable

Easy speed control

Torque

Constant torque at all speeds and at start

Lagging

Lag with any materials, also can be knurled

Savings

Save by reduced maintenance & downtime

Easy Retrofit

Uses standard bearing housings

Clean

Ideal for HACCP inspected areas